Are there any receptacles that can be welded in the HHS-series?

Are there any receptacles that can be welded in the HHS-series?

Yes, we have 2 types of recepacles that can be welded.

Either with weld nibs, where it is needed to spot weld the receptacle to your panel,

Or without weld nibs, where the welding happens around the receptacle.

Both types are available either in steel zinc plated or steel with oil coating.

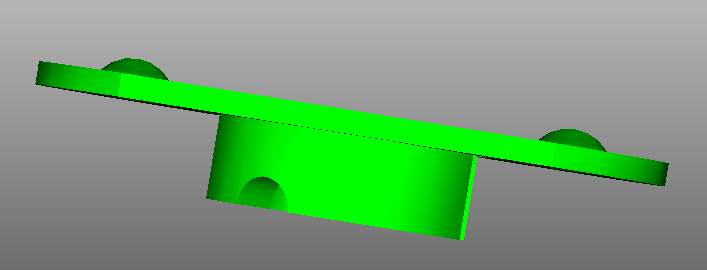

This is the type with welding nibs:

This process is used in mass production with which you need a special machine to do it.

With this machine you combine pressure while also pushing a current through the weld nibs.

The receptacle that needs to be welded on by traditional manner looks like the following receptacle:

As mentioned, this receptacle needs to be welded on by the traditional manner such as TIG or MIG welding.

This process takes much longer than the spot welding.

Here's drawing of how you'll need to weld this receptacle:

There is also a difference in the plating. When needed to weld a receptacle to a panel,

The choice is between either a zinc plated or an oil coated steel receptacle.

With the zinc plated receptacle, you melt the zinc layer on top of the receptacle.

This causes discoloring and gives the receptacle a "dirty" look.

On the other hand there is the oil coated receptacle.

Here you just need to clear/wipe off the oil coating before welding the part to the panel.

The part number with weld nibs is HHSRFWZ (zinc plated) or HHSRFWB (blank/oil coated)

Without weld nibs, the part number is HHSRFWSZ (zinc plated) or HHSRFWSB (blank/oil coated)